Jeans back then weren’t fashion statements. They were survival gear for miners, railroad workers, and ranch hands. Denim was tough, but not invincible. Pockets tore, flies split, seams gave out. One tailor, Jacob Davis, kept hearing the same complaint: the pants didn’t last.

So he tried something new. He reinforced the weak spots with copper rivets—hardware borrowed from industrial use, not fashion. The result? Jeans that held up for months, even years. Davis saw the potential but lacked the funds to patent the idea. He partnered with his fabric supplier, Levi Strauss, and in 1873, they launched the riveted jean. It was built for function, not flair.

🛠️ From Workwear to Icon

Word spread fast. Workers loved the durability, and demand exploded. What started as a practical fix became a symbol of toughness. As denim shifted from workwear to everyday wear, rivets came along for the ride.

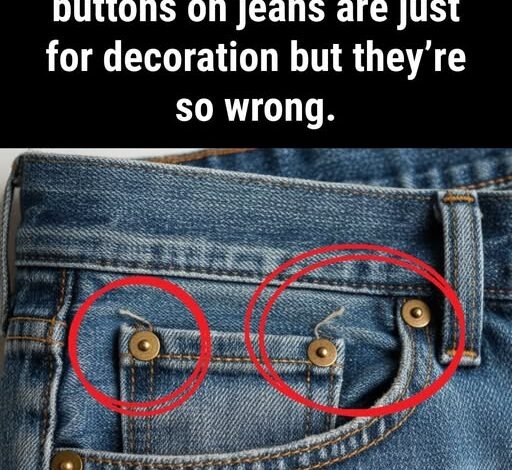

Technically, rivets are straightforward—usually made of copper or brass, metals that resist rust and handle stress. You’ll find them at the front-pocket corners, where strain builds from movement and weight. Older styles even had rivets near the fly and back pockets, though complaints from horseback riders (scratched saddles, torn leather) led manufacturers to hide or relocate them.

The genius of the rivet lies in how it distributes tension. Instead of fabric tearing at a single point, the rivet spreads the force, keeping the material intact. Anyone who’s owned jeans without rivets knows how quickly those corners fray.